Product Center

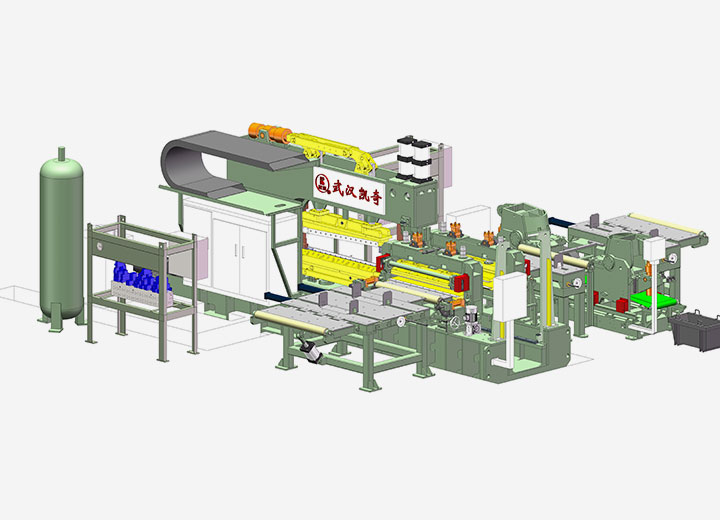

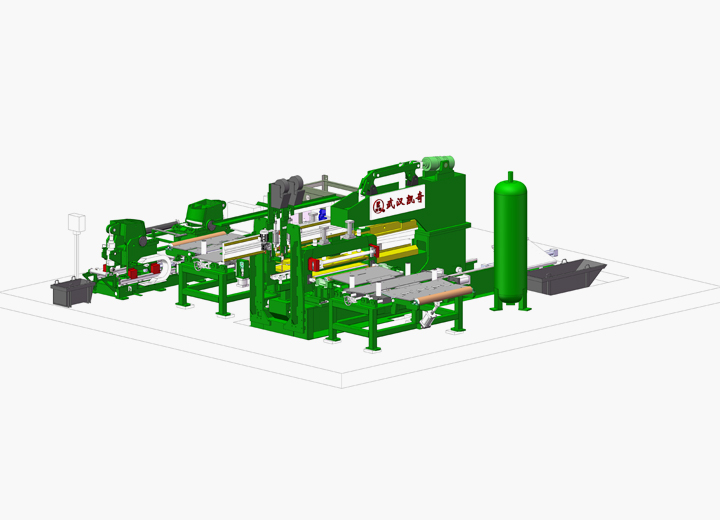

Lap Welding Machine

Lap welding machines are extensively used in cold-rolling continuous treatment lines of strip steel. In 1998, the first lap welding machine researched and developed by the Company came on the scene, a first example of lap welding machine localization.

Thanks to years of unceasing exploration and research of core technologies for lap welding, the Company has researched, developed and produced three major types of lap welding machine: type C narrow lap welding machine, type O narrow lap welding machine, and narrow-band type C narrow lap welding machine, to meet the welding requirements of different materials of strip steel on various cold-rolling continuous production lines.

The "FMY series" single welding wheel and single roller medium frequency narrow lap welding machine and the "FMYS series" double welding wheel and double roller arrow-lap narrow lap welding machine developed and manufactured by Wuhan Kaiqi have won provincial and municipal scientific progress awards for many times with a number of national invention patents and utility model patents.

- Carbon steel

- Silicon steel

- Stainless steel

- Other steel types (T), etc.

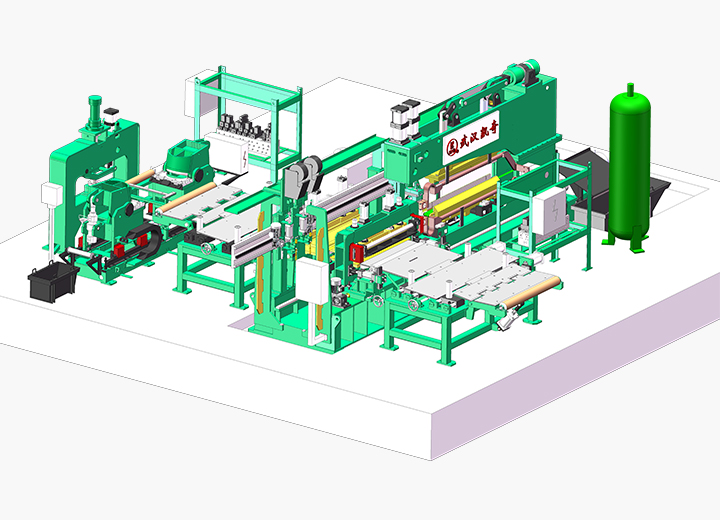

Gas Shielded Welding Machine

The Company researched,developed and manufactured its first gas shielded welding machine in 2005, which was successfully applied in the strip steel production line.

Thanks to years of unceasing exploration and research, the gas shielded welding machine has been used in batch, operated stably at the worksite and well recognized and praised by the users in the industry.

The "NZ series" gas shielded welding machine of Wuhan Kaiqi has won provincial and municipal scientific progress awards for many times and various national invention patents and national utility model patents.

- Carbon steel

- Silicon steel

- Stainless steel

- Other steel types(Ti, AI)

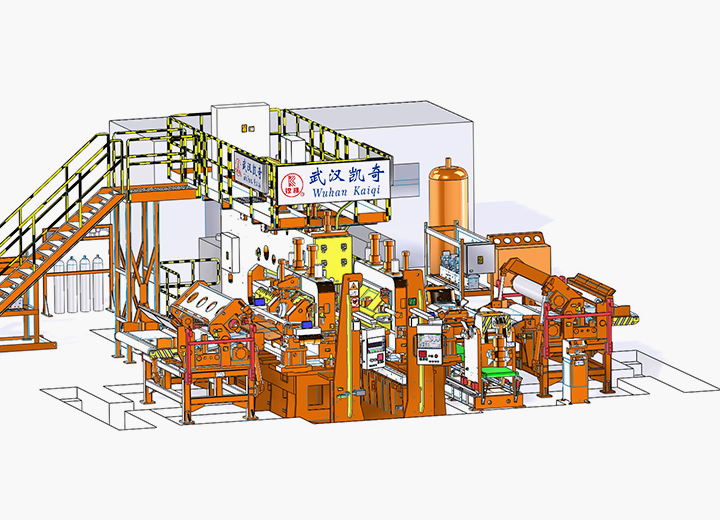

Hybrid Welding Machine

The Company researched,developed and manufactured its first hybrid welding machine in 2012, which was successfully applied in the continuous strip steel production line.

The welding machine breaks through the traditional design concept, integrates the advantages of "gas shielded welding" and "lap welding", and applies the latest self-designed process control technology, which can meet the welding needs of users for cold-rolled (hot-rolled) plates on one production line. With strong adaptability to changes in strip steel varieties and wide applicability, the product is highly adaptable to the needs of this kind of production line

- Carbon steel

- Silicon steel

- Stainless steel

- Other steel types (Ti)

Laser Welding Machine

In 2010, the Company developed and manufactured its first laser welding machine as the first example of laser welding machine localization, which has been successfully applied to the continuous strip steel production line.

After more than ten years of continuous exploration and research on the core technology of laser welding, the Company has broken through the traditional laser welding technology at home and abroad, and successfully applied solid laser welding technology to strip steel continuous production lines in 2012. The solid laser welding machine offers stable welding quality and is more efficient, energy-saving, cost-effective, easier to operate and maintain than traditional gas laser welding machine. It has been put into use in large quantities for all production lines in the strip steel cold rolling industry, and is deeply recognized and praised by customers in the industry.

The "GD series" high-power optical fiber (solid) laser welding machine and the "GQ series" high-power CO2 (gas) laser welding machine have won scientific and technological progress awards for many times and various national invention patents and national utility model patents.

- Carbon steel

- Silicon steel

- Stainless steel

- Other steel types (Ti)

About Us

Wuhan Kaiqi Metallurgical Welding Equipment Manufacturing Co., Ltd. (formerly known as "Wuhan Special Welding Equipment Factory" founded in 1988) is a professional company engaged in the R&D, design and production of steel plate and strip continuous online welding equipment. Wuhan Kaiqi is located i...

-

17Exporting countries

-

35Industry experience

-

43Our patent certificates

-

1270Promoting products

News Center

Customer Service

-

01

Market survey

-

02

Project planning/plan formulation

-

03

Bilateral communication

-

04

Technical agreement/contract conclusion

-

05

Design review

-

06

Detailed design

-

07

Parts manufacturing/elements and components purchase

-

08

Inspection/warehousing of purchased parts

-

09

Equipment assembly/factory commissioning

-

10

Onsite installation and commissioning for customers

-

11

Production

-

12

Quality tracking

After-sales service

Continuous upgrading